What is Normal Veneer Stone?

Normal Veneer Stone is a natural stone product obtained from quarries around the world and is split from real slate. Sourcing our products from different geographical locations results in a stunning, natural product available in a colour to suit every application.

Because our products are exactly as nature created millions of years ago, every piece is different in stratus, three dimensional accentuation and feel, graining and avariances of colour hues. Each piece has its own natural and individual beauty, making it impossible to “sequence” or match any two pieces for applications

It requires a high degree of skill and “hands-on” labour to split the slate into very thin layers while applying a glass fibre reinforced polyester resin (GRP) for a strong bond producing the backing for the sheets of Normal Veneer Stone. The high degree of adhesion achieved between the slate and the GRP makes the product more stable and adds amazing flexibility.

We also offer Normal Veneer Stone in colours found in natural sandstone, a sedimentary rock consisting of grains of sand which mainly contain quartz. It is mined from sand pits in Northern Germany and bonded vertically with thermoplastic binders onto large sheets. The colour variations of the sand range from white quartz to dark brown.

Produced with great skill and experience, only from selected and suitable sand pits, the relief-like progressions of the sediment layers make each sheet a truly unique piece.

We apply a fabric mesh-structure for great flexibility.

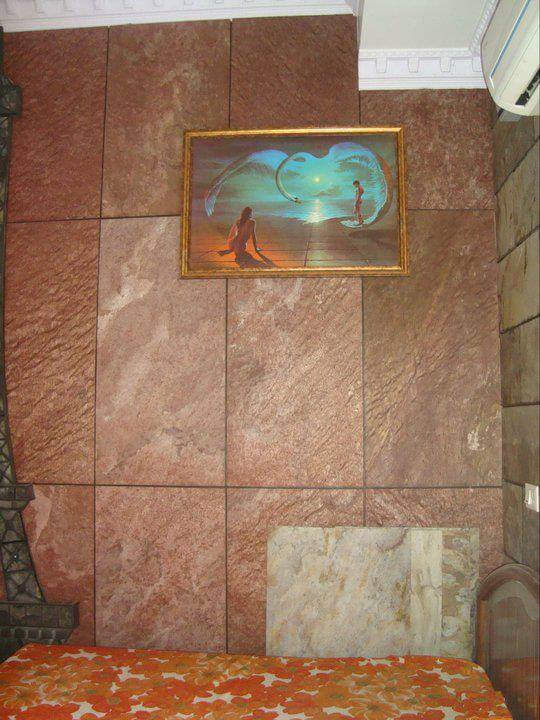

Every product in our Normal Veneer Stone range has an inherent and natural beauty, enabling designers to add a spectacular appearance, texture and a unique touch of luxury to an enormous variety of applications and locations.

Uses For Normal Veneer Stone

By bringing Normal Veneer Stone to market, we are offering previously unimagined levels of flexibility in design and use that only our unique real stone products can deliver. Real stone in our unique Normal Veneer Stone form can be cut, bent and shaped to fit any surface area, regardless of whether it is flat, curved or even a mix of the two.

By bringing Normal Veneer Stone to market, we are offering previously unimagined levels of flexibility in design and use that only our unique real stone products can deliver. Real stone in our unique Normal Veneer Stone form can be cut, bent and shaped to fit any surface area, regardless of whether it is flat, curved or even a mix of the two.

Because of its unbelievable bendiness, Normal Veneer Stone can be used in applications previously undreamt of. Pillars, walls, ceilings, columns, furniture, luggage and more – can now all be made to look absolutely stunning, clothed in the beauty of real stone.

Reception areas, entrances, boardrooms, hotel foyers, restaurants or any other interior area can all be given a unique touch of class which comes from using this beautiful natural product. In the home its uses extend to bathrooms, kitchens, hallways, bedrooms or anywhere that would benefit from a luxurious, striking and altogether dramatic appearance.

What’s more, being incredibly lightweight, Normal Veneer Stone is simple and quick to install, saving time and money. It has the added advantage of being easy and economical to ship, to store and handle. As if that were not enough, it is also extremely eco-friendly in production and sustainability.

Installation Guide

To cut and size Stone Veneer all standard woodworking equipment can be used with carbide tooling. Table Saw; Router; Circular Saw; Laminate Trimmer; Miter Saw; Radial Arm Saw. For using panels with Stone-Veneer® on both sides, it is recommended to score them because the stone surface on the backside tends to slightly splinter. Follow all equipment manufactures safety rules.

The actual substrate it is to be applied to is almost unlimited. All wood and lightweight materials are suitable. If the Stone Veneer is only applied on one side of a carrier material, it is important to have a counter balance on the other side for stability. Mechanically mounted panels which have the Stone Veneer on one side, need a craft paper or foil backing of at least 150 g / m2 (3.6128 pound/cubic inch). If applied as floor or wall panels, different climate conditions have to be taken into consideration.

For any substrate you use there are a few standard guidelines to follow:

The two products to be adhered together must be clean of dust, debris, grease and oils.

Use a suitable adhesive for your substrate. We recommend 3M550, Boss PU25 & Kerakoll Super-Flex Eco.

The Stone Veneer adhesive requirements vary with the factory backing used on the veneer.

Polyester backed (standard backing) and Fleece backed (optional) can be adhered with our recommended 3M550, Boss PU25 & Kerakoll Super-Flex Eco. product. If alternative un-recommended adhesives are used, from experience, sometimes these products can react with the backing material and cause problems.

When using a hot or cold hydraulic panel press to bond the Stone Veneer to a substrate it is recommended you use a soft “buffer” sheet (such as a thin rubber sheet) on the Stone Veneer because of the natural 3-Dimensional surface variances.

Care, Handling and Cleaning Guidelines for Stone-Veneer

1. Care and Handling

Stone Veneer is a real and natural slate product and it is as porous as any natural slate would be. The slate may absorb the oils found on your hands and fingers. Follow the cleaning instructions to remove any smudges. Wearing gloves when handling these materials will minimize the amount of cleaning required.

2. Cleaning

Any impurities splashed or spilled on the Stone Veneer should be removed as soon as possible. In doing so warm water and a lightly moistened lint free cloth often suffices.

If the impurity or stain is not easily removed we recommend washing the surface with a soft lint free cloth moistened with a mild dish washing liquid and warm water solution. Alternatively, Mapei Cleaner L should be used and it is advised that a test area is done first.

If you do use any additional cleaners, test them on an inconspicuous area first to make sure they will not adversely harm or stain the surface of the Stone Veneer.

If the Stone Veneer is being used in any wet areas such as kitchen backsplashes, near a food preparation area or sink it does need to be sealed. Bacteria and everyday stains and dirt can accumulate in the slate’s pores making it difficult to clean. The natural minerals present in your water can also accumulate in the stone’s pores. This is most noticeable in bathroom applications and shower/bath areas.

There are a variety of stone sealers on the market today and when applied according to the manufacturer’s recommendations will seal the pores on the Stone Veneer surfaces. We have tested Tec™ EnsealantSB with very satisfactory results. It is a solvent based Stone Enhancer and Sealer.

3. Touch Up

Real slate will scratch when dragged across another piece of slate or a hard object. Many times what you see is the residual stone dust from the scratch. Cleaning as stated above will remove the stone remnants. If it is a much deeper scratch wiping a small trace of vegetable oil with your finger tip into the scratch will help prior to a light cleaning as above. Please note that Stone Veneer is a real slate stone. There are natural inconsistencies, fractures, color and surface variations and imperfections visible on the surfaces. These are quite normal and do not constitute faults or imperfections.

Fixing of the Normal Stone Veneer Sheets

Samples of the Stone Veneer have been tested by Kerakoll for FIXING and a product called Super-flex eco has been recommended. The Super-flex eco is actually part of their flooring range but has proved to be the best product Kerakoll produce for securely fixing the Stone Veneer sheets.

Samples of the Stone Veneer have been tested by Kerakoll for FIXING and a product called Super-flex eco has been recommended. The Super-flex eco is actually part of their flooring range but has proved to be the best product Kerakoll produce for securely fixing the Stone Veneer sheets.

The Super-flex eco is a one-component, solvent free, ready to use flexible thixotropic sililated based adhesive. For application, it is recommended to fully cover the substrate using a 4mm knotched trowel. The Stone Veneer sheets will instantly grab to the surface but still allow a little movement for the sheets to be adjusted into place. The sheets can either be butted up against each other or a small grouting joint (recommended) can be left leaving a tile effect (grouted using Kerakoll Grout), either option is down to personal choice.

Application is a full covering of the substrate using an 4mm knotched trowel. The 3M550 or Boss PU25 is only available in 600cc sausage tubes and the coverage is approx 1.5 square meters per tube. A special applicator gun is advised for extracting the adhesive from the tube.

It is always recommended that a professional trades person fits these products and a full understanding of the technical report is clear (available on request or via the Kerakoll website).

Grouting of the Stone Veneer Sheets

Samples of the Stone Veneer have been tested by Kerakoll for the GROUT JOINTS and a product called ULTRACOLOR PLUS cementitious mortar has been recommended.

The Ultracolor Plus is a fast setting and drying, high performance, polymer modified, anti-efflorescence, water repellent grout for joints from 2mm to 20mm that is available in 26 colours. It also is combined with Drop Effect and anti-mould with BioBlock technology.

If a gap between the sheets is preferred then this is the product to use. Firstly pick which colour grout best suits the Stone Veneer sheet. It is recommended to grout the joints after the sheets have been fixed in place and left to set for at least 24 hours. Prior to grouting, tape the Stone Veneer sheet edges to avoid the Ultracolor Plus grout getting onto the surface of the stone veneer sheet, mix the required amount and then fill the joints following the Kerakoll mixing and grouting guidelines. Drying / curing time is approx 12 hours based on the below coverage rate.

Based on a standard sheet size of 1220mm x 610mm….. and a 10mm wide x 5mm deep joint, the coverage works out at approx .2 of a kg per square meter.

Technical Specification

Standard sheet size 1220mm x 610mm (4ft x 2ft) & Larger sheet sizes are available in certain colours to a maximum sheet size of 2800mm x 1250mm. These large sheet sizes are not stock items and are made to order. Please allow 3 to 5 working days. Bespoke sizes to suit your specific requirement are available to order. Please allow a 3 to 5 working days to lead time.

Technical Properties (raw material)

General |

||

Front |

Real stone |

|

Back(*) |

Glass fibre fabric in polyester resin matrix |

|

Temperature limits |

-58 /+203 °F |

|

Formaldehyde |

Stone-Veneer is formaldehyde-free |

|

Thermal expansion (194 °F) |

0.5 – 0.8 mm/m (≈0.08 %) |

|

Fire behaviour: |

Individual assessment |

|

Specific Surface |

colourful slate |

quartzite slate |

Thickness (mm) |

1.0- 1.5 |

1.0- 2.0 |

Weight per square metre (lbs) |

2.2 – 3.3 |

2.2 – 4.4 |

Water absorption (%) ASTM C-121 |

2.5 |

1.9 |

Average abrasion (mm) IS: 9162-1979 |

0.7 |

0.9 |

Maximum abrasion (mm) IS: 9162-1979 |

0.8 |

1.0 |