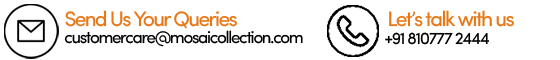

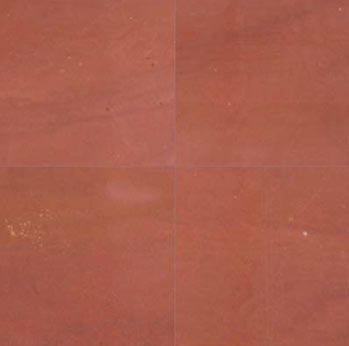

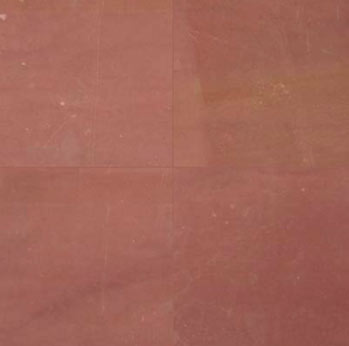

Dholpur Red

Dholpur Red Sandstone or as is popularly called Agra Red Sandstone got its name from the quarries location and its proximity to Agra City famous world over for being the host of one of the Seven Wonders of the World THE “TAJ MAHAL”. Sandstones take its color based on the minerals proximity to the rock at the time of formation. Red color is imparted due to the presence of Iron Oxides near the bedding planes. This is hard wearing sandstone designed for conformity of color and a contemporary styling.

Since ages this sandstone has not shown any weathering effects. For example; during the archaic period it was expansively used in the construction of Indian temples, Agra Fort, Delhi Red Fort and many other forts. Since; this sandstone is very responsive towards a variety of finishing like rubbed, honed, polished or sandblasted, shot blasted with hand cut or sawn edges, Agra Red’s decorating versatility remains incomparable. For this reason Agra red sandstone has become many architects’ favorite constructing material. The large choice of sizes allows for some creativity in laying design. The color of this sandstone ranges from light to dark red.

Owing to its strength, durability, resistance to abrasion and environmental weathering, acid and alkali resistance and advantage of easy handling and availability has made Indian Sandstone the material of choice for construction and making artifacts and decorative items. It has variety of applications in roofing, flooring, paving, paneling, beams, pillars, doors and window sills. It has been found most suitable for carving screens. Due to its excellent workability it is fit for both exterior and interior uses.

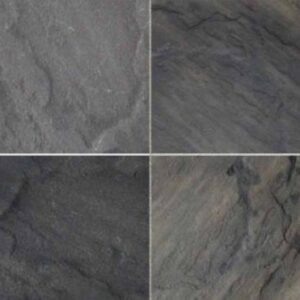

Dholpur Red Sandstone is available in various finishes such as natural cleft, flamed, polished, honed, bush hammered, sawn, acid washed, antique finish and sand blasted to suit different applications. The finish and smoothness of tiles and slabs of sandstone depends on the finish of edges, which is available in machine cut, sawn, hand chiseled, hand dressed and chamfered, beveled. The edges play a major role in the overall appearance of the architecture they are used in.

Specification

| Classification | Sand Stone | ||

| Quarry Deposit | Compact | ||

| Quarry Excavation | Block | ||

| Chisel Splitting | Not Possible | ||

| Gang Saw Sawing | Possible | ||

| Offered in | Block, Slabs and Tiles | ||

| Finishes Offered | Natural, Sandblasted, Honed, Brushed | ||

| Standard Specifications | Random Slabs 2cm and 3cm thick | ||

Cut to size tiles 20mm and 30mm Thick

* Only in Higher Thickness |

|||

| Tailor-Made Specifications | Possible | ||

| Carved Articles | Possible | ||

| Recommended Applications | Interiors & Exteriors | ||

| Suitability | Medium to Low Traffic | ||

| Consistency | Fair | ||

| Fragility | Sound | ||

| Delivery | 2 to 3 weeks |

Technical Specification for Dholpur Red

| Technical Information | Value | ASTM/ INDIAN Standards |

| Water absorption, % by weight | 0.15 | C-97 |

| Density (Bulk specific gravity) | 2.65 | C-97 |

| Modulus of rupture, N/ mm2 | Dry – 11 Wet – 15 |

C-99 |

| Compressive Strength N/ mm2 | Dry – 117 Wet – 100 |

C-170 |