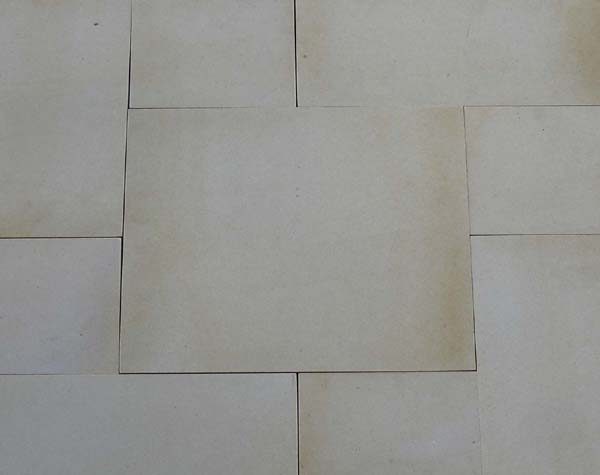

Mint

Mint Sandstone also called as Tinted Mint or Himalayan Sandstone is beautiful natural Sandstone with a mixture of greenish yellow and buff colors. With its natural tones and shades, Tinted Mint paving blends in with any surrounding. Due to the individual characteristics of hand quarried natural stone, each piece has its own unique look and may vary in color, texture and thickness from other pieces of the same type of stone. There is a variation in surface texture, from being reasonably smooth whilst others have a bit of a split finish and irregular layers. The tiles remain non-slip when wet.

The subtle color variations ensure that this product looks stunning in any application. Perfect for the almost any environment it offers warm, neutral colors that stay cooler in the heat of summer. Bringing you back to Mother Nature with our Mint Sandstone that adds an unmistakable sense of style and warmth to your decor – just as nature intended.

Honed finish results from the natural finish tiles being polished to give a smooth surface, free of any irregularities. The color becomes much more even and very light, when wet there may be it bit of underlying color showing. Mint Sandstone is especially useful in exterior claddings in sea shore buildings due to acid and thermal resistant properties. As such the effect of saline winds is negligible on Mint Sandstone. Mint Sandstone Circle stones can create a fantastic focal point within a garden either on its own or as a feature area within a patio.

Mint Sandstone is available in Honed or Sandblasted finishes. It is also available in pool coping and step tread formats. This sandstone is ideal for use in exterior courtyards, patios and landscaped areas. Himalayan Sandstone tiles can also be used as a wall cladding finish.

Mint Sandstone is suitable for use as Flooring, walling and exterior Landscapes due to its physical and chemical properties. It has a very smooth natural split surface. It is also suitable for carving and making stone handicrafts.

Mint Sandstone is available in various finishes such as natural cleft, flamed, polished, honed, bush hammered, sawn, acid washed, antique finish and sand blasted to suit different applications. The finish and smoothness of tiles and slabs of sandstone depends on the finish of edges, which is available in machine cut, sawn, hand chiseled, hand dressed and chamfered, beveled. The edges play a major role in the overall appearance of the architecture they are used

Specification

| Classification | Mint | ||

| Quarry Deposit | Compact | ||

| Quarry Excavation | Block | ||

| Chisel Splitting | Not Possible | ||

| Gang Saw Sawing | Possible | ||

| Offered in | Block, Slabs and Tiles | ||

| Finishes Offered | Natural, Sandblasted, Honed, Brushed | ||

| Standard Specifications | Random Slabs 2cm and 3cm thick | ||

Cut to size tiles 20mm and 30mm Thick

* Only in Higher Thickness |

|||

| Tailor-Made Specifications | Possible | ||

| Carved Articles | Possible | ||

| Recommended Applications | Interiors & Exteriors | ||

| Suitability | Medium to Low Traffic | ||

| Consistency | Fair | ||

| Fragility | Sound | ||

| Delivery | 2 to 3 weeks |

Technical Specification for Mint

| Technical Information | Value | ASTM/ INDIAN Standards |

| Water absorption, % by weight | 0.15 | C-97 |

| Density (Bulk specific gravity) | 2.65 | C-97 |

| Modulus of rupture, N/ mm2 | Dry – 11 Wet – 15 |

C-99 |

| Compressive Strength N/ mm2 | Dry – 117 Wet – 100 |

C-170 |